Understanding Stretch Film Cling Strength

August 9, 2025

Stretch Film Elasticity

August 12, 2025Stretch Film Strength

Stretch Film Strength: Key Factors and How It’s Measured

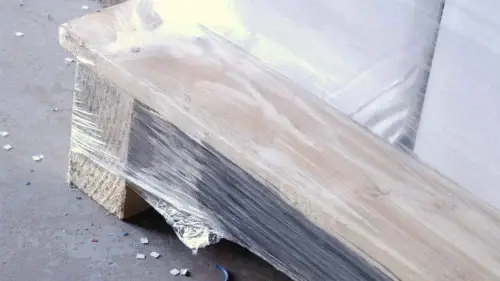

In industrial packaging, stretch film strength is more than just a technical metric—it’s a critical performance indicator that directly affects product safety during storage, transport, and handling. A film that lacks mechanical strength, no matter how well it clings, will fail under pressure.

What Is Stretch Film Strength?

Stretch film strength refers to the film’s ability to withstand mechanical forces such as tension, puncture, tearing, and sudden pressure. In other words, it defines how durable and reliable the film is when exposed to stress during packaging or logistics.

A high-strength stretch film provides better load stability, reduces film breakage, and ensures consistent performance—even in high-speed operations or demanding conditions.

What Affects the Strength of Stretch Film?

Several technical factors influence the mechanical strength of stretch film:

Polymer Quality and Blend

The type of polyethylene used (e.g., LLDPE, mLLDPE) and the inclusion of reinforcement additives significantly impact tensile strength.Production Technology (Cast vs. Blown)

Blown stretch films typically offer higher resistance to tearing and puncture, making them ideal for heavy-duty packaging.

Cast films offer better clarity and unwinding smoothness but may be less durable in extreme applications.

Multi-Layer Construction

Films with 5 or 7 layers can distribute stress more efficiently and provide enhanced durability.Thickness (Gauge or Micron Rating)

Thicker films usually provide greater strength, although excessive thickness may reduce flexibility.Elastic Memory (Recoil Force)

A strong film should not only stretch but also exert the right amount of holding force to secure the load after wrapping.

How Is Stretch Film Strength Measured?

There are multiple standardized methods to evaluate stretch film’s mechanical strength:

1. Tensile Strength (ASTM D882)

This test stretches the film until it breaks, measuring how much force (in MPa or N/mm²) it can withstand before failure.

2. Puncture Resistance (ASTM D5748)

A metal probe is pushed through the film at a fixed speed to determine how much energy the film can absorb before rupturing.

3. Tear Resistance (ASTM D1922)

This test determines the force required to propagate a tear through the film, which is crucial for wrapping sharp or irregular loads.

Karen’s Industrial Stretch Films – Built to Endure

At Karen, one of the top industrial stretch film manufacturers in Iran, strength is not an afterthought—it’s engineered into every roll. Through advanced multilayer technology and carefully selected resins, Karen films offer exceptional durability and performance.

🎯 Why Karen’s Stretch Films Stand Out:

High tear and puncture resistance

Consistent stretch ratio with minimal film breakage

Suitable for wrapping sharp-edged and heavy loads

Reliable performance in a wide range of temperatures

Why Strength Matters

Choosing a film that lacks mechanical integrity leads to frequent breaks, lost time, increased film usage, and potential damage to goods in transit. On the other hand, high-strength films like those from Karen allow for secure wrapping with fewer layers—improving efficiency and lowering total packaging costs.

When your products move, strength matters.

When strength matters, Karen delivers.

Below, you can watch the video of Karen stretch film resistance.